Epoxy resin is one of the most versatile materials, known for its strength, durability, and chemical resistance. But have you ever wondered how it’s made? Let’s explore the step-by-step manufacturing process of epoxy resin in 2025 and the materials involved.

Key Raw Materials Needed for Epoxy Resin Production

The primary raw materials in the production of epoxy resins include:

Step-by-Step Manufacturing Process of Epoxy Resin

The production of epoxy resin occurs in a specialized chemical vessel called a reactor.

1️⃣ Initiating the Epoxy Formation

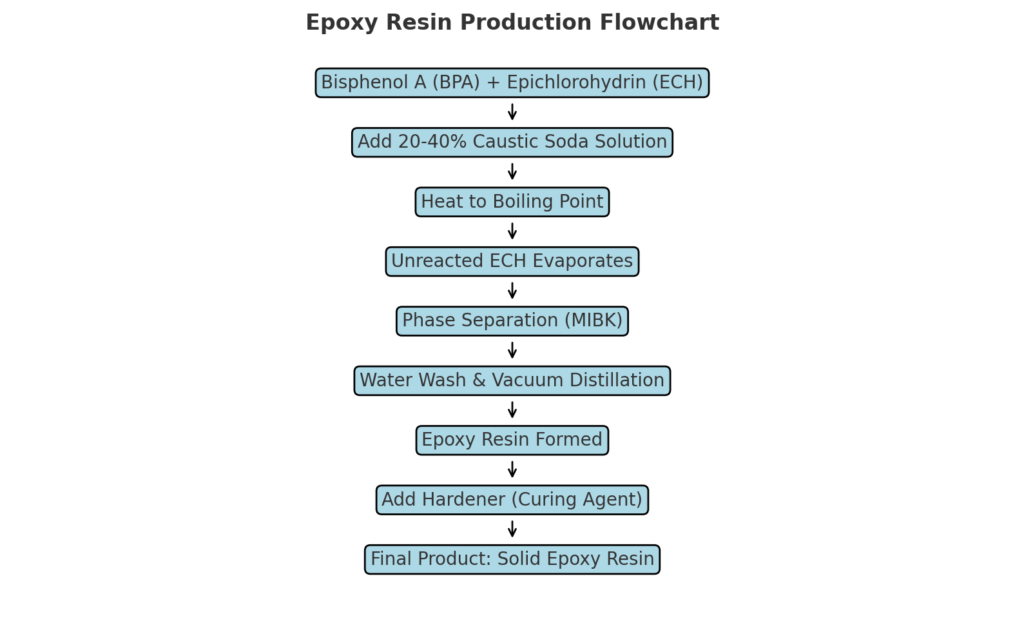

📌 The process begins by combining the base resin, bisphenol A (BPA), with epichlorohydrin (ECH) to initiate the epoxy formation.

2️⃣ Addition of Caustic Soda for Chemical Reaction

📌 A 20-40% caustic soda solution is added and brought to the boiling point. This step ensures unreacted ECH evaporates and exits the reactor.

3️⃣ Purification & Phase Separation

After the unreacted ECH evaporates, the mixture undergoes phase separation with the addition of an inert solvent like methyl isobutyl ketone (MIBK). The separated resin is then washed with water and further purified through vacuum distillation.

4️⃣ Curing Process & Hardener Application

Once the epoxy resin is synthesized, it requires a hardener (curing agent) for solidification. Common hardeners include amines, acids, or anhydrides, which trigger a cross-linking reaction, transforming the liquid resin into a durable, solid material. The curing process can occur at temperatures ranging from 5°C to 150°C, depending on the type of hardener used.

5️⃣ Customization with Additives

📌 Manufacturers enhance the resin by adding custom additives to adjust:

Epoxy Resin Process Flow Diagram

Frequently Asked Questions (FAQs) About Epoxy Resin Manufacturing

1️⃣ What is the main raw material used in epoxy resin production?

The main raw materials used in epoxy resin production are Bisphenol A (BPA) and Epichlorohydrin (ECH), which react to form the epoxy functional group.

2️⃣ Is epoxy resin environmentally friendly?

Mostly used epoxy resins contain petroleum-based chemicals, but bio-based epoxy resins are emerging as a more eco-friendly alternative..

3️⃣ How long does epoxy resin take to cure?

The curing time is based on two factors:

- The type of hardener used

- Temperature

🚀 The Future of Epoxy Resin Manufacturing in 2025 & Beyond

The future of epoxy resin is shaped by technological advancements. Epoxy resin production is becoming more efficient and eco-friendly. Innovations like bio-based resins, automated reactors, and AI-driven quality control are shaping the future of this industry.

💬 What’s Your Take?

What do you think about the latest innovations in epoxy resin manufacturing? Share your thoughts in the comments!